WHAT IS THE VALVE?

- A valve is a device that controls not only a flow, but also the rate, the volume and the pressure, direction of liquids, gases, toxic gases, slurries through a pipeline chute or passageway.

REASONS FOR FITTINGS?

- Complete isolation

- Throttle

TYPES OF VALVES:

Basically the valve types are classified into 8 types there are,

- Screw down valve

- Parallel slide valve

- Gate valve

- Check valve

- Ball valve

- Butterfly valve

- Diaphragm valve

- Bellow seal valve

SCREW DOWN VALVE:

- It uses threaded spindle to control valve position

There are four types of valve seat and geometry

- Mitre valve

- Flat valve

- Globe valve

- Hemispherical valve

PARELLEL SLIDE VALVE(PSV VALVES):

- It used a stream system where full flow and no control is required

- Parallel disc forming valves lids are kept in the contact with valve seat by a spring

- Tight seal to flow is maintained by differential pressure acting on valves seat and lids.

GATE VALVE:

- It general service valve, it operates (open/close) by a disc or gate that slides down through the valve to block the flow.

RECOMMENDED USES:

- Fully open/close, non-throttling

- Infrequent operation

- Minimal fluid trapping in line

- These valves are often described in terms of sealing element. (Eg :solid wedge, parallel slide, parallel double disc and split wedge

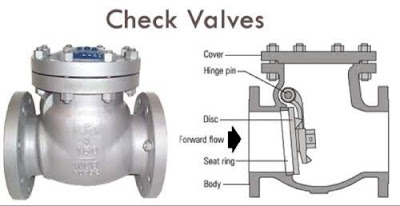

CHECK VALVE:

- Check valves are described as reflux, non-return, back pressure, retaining valve.

- The check valves are designed to prevent back flow. Fluid flow in the desired direction opens the valve while backflow forces the valve closed.

- Most check valves are based on either swing concept or lifting concept. Some common types are,

- Swing check valve

- Split check

- Dual plate check

BUTTERFLY VALVE:

- A flat plate is positioned in the center of pipe. The plate is connected to the Rotating handle which turns the plate either parallel or perpendicular to the flow.

- A tight seal obtained by a synthetic rubber fitted around the edge of the plate.

- Valve can be used with on actuator on remote.

BALL VALVES:

- Valve consists of a ball having a hole through its center.

- Ball fitted between the two seats of synthatic material.

- Quick Operation by a Rotating handle.

DIAPHRAGM VALVE:

- Diaphragm valve is a linear motion valve that is used to start, regulate and stop fluid flow.

- The name is derived from its flexible disc which mates with a seat located in the open area at top of the valve body to from seal.

BELLOW SEAL VALVE:

- This type of valve used on nuclear submarine.

- Used as stream stop / bypass valve

- Consists of welded valve body with removable bonnet assembly.

- Valves sealing is achieved by bellows.

SELECTION OF VALVES:

- The substance to be handled and required flow rate.

- The ability of valve to withstand the maximum working pressure and temperature.

- The ability of valve to resist attack by corrosion or erosion.

- Actuator requirements

- Maintenance and repair requirements

1 Comments

there is no link

ReplyDelete